AKGEI

Excellence in Rail

Excellence in Rail

Since 1978

RFID PRODUCTS IN

CollaBoration

With BARC

ISO 9001:2015

Products

Digital Current Integrator (DCI)

Designed in collaboration with Department of Atomic Energy (DAE), Government of India. Manufactured by AKG Electronics Industries.

-

Measures DC or avg. value of bipolar currents from 50 pA to 100uA with accuracy approx. +/- 5% (of reading)

-

Measures accumulated charge with accuracy approx. +/- 2% (of reading)

-

Five auto-selectable full scale input ranges from 10nA to 100uA.

-

RS-232 Communication | Large LCD + Multifunction

![IMG_20160618_143005497 (2)[2].jpg](https://static.wixstatic.com/media/a3d9a3_f500f7fd868f4898ad785ae34d7d30ac~mv2_d_4008_5344_s_4_2.jpg/v1/fill/w_413,h_549,al_c,q_80,usm_0.66_1.00_0.01,enc_avif,quality_auto/IMG_20160618_143005497%20(2)%5B2%5D.jpg)

TLBI (Tokenless Block Instrument)

It is a single line Block Instrument (modified instrument) designed to work on Carrier frequency 1800 Hz or 2700 Hz and modulating frequency (65 Hz and 85 Hz). A pair of block Instruments are connected electrically through overhead or cable to control a single line Block section. It is installed at Station A & Station B and both the stations are linked through Tokenless Block Instrument and telephone. This being FAIL SAFE equipment, which is obtained by a mechanically operated rotary type handle, called Block Handle, located in the front on the lower part of the Block instrument. The handle has force drop locking arrangement which prevents the single handed operation of the device from one station without acknowledging the other Station. Token less block instruments (Handle Type) are used in Indian Railways for obtaining ‘line – clear’ in single or reversible line for electrified as well as non electrified sections. No overhead wire connection is required for this equipment and it posses high immunity to noises (resulting from local electrical or overhead traction wires), it performs sending, receiving, push – back, shunting or canceling ‘line clear “operation for trains. It is vetted as a fail – safe equipment by the Research Design and standard Organization of Indian Railways (RDSO). Since 1989 to the present day, it is performing at a 100% success-rate without occurrence of any accident. A set of FM transmitter & receiver forms the heart of this equipment and is responsible for the low level communication from one station to other and in combination with precisely designed durable and reliable electrical, electro – magnetic, contacts / relays / switches with other mechanical components, the equipment performs authoritatively fail –safe operations. All operations are instrumentally interlocked, given clearance, cannot be withdrawn without verbal confirmation over telephone, along with instrumental acknowledgement from the other end. However secondary arrangements are also kept in the instrument for verbal communication, if needed, between stations through telephones. While transmitter or receiver is in use, the telephone circuit becomes isolated from signal line and vice-versa. Continuous R & D in the area of electrical, electronics, mechanical and metallurgy has made it a state of the art technology to meet the time – to – time demand for highest reliability along with the changes required for local and environmental suitability.

Technical Specifications:

The instrument is designed to work on 24V DC voltage (normal) with variation between 19.2V to 28.8V. It works on Frequency modulated (FM) system utilizing FM TRANSMITTER & RECEIVER to immune from the effects of extraneous interference. Maximum Current drawn by the internal circuit is not more than 700mA and by the line circuit is not more than 110 mA during normal sequential operation. The instrument is suitable to work with a temperature variation from 0°C to 55°C with relative humidity of 95% at 40°C. Locking and sealing facilities are also provided in the instrument to prevent un-authorized tampering.

Transmitter & Receiver

The Transmitter & Receiver (Tx & Rx) forms the heart of this equipment and is responsible for the low level communication from one station to the other.

This latest version of AKGEI make frequency modulated Transmitter & Receiver model D-96 is based on IRS specification: IRS S/90-2001 (Amendment-1). It has been so designed that it remains fully downward compatible with the previous AKGEI model M-5 Tx & Rx to avoid any operational problems in the field.

The Transmitter & Receiver unit is designed to work at 24 V DC with input supply variation between 19.2 V DC & 28.8 V DC and carrier frequency 2700/ 1800 Hz and modulating frequency of 65. 85 Hz. The maximum power consumption of Tx & Rx are 1.2 W and 8 W at 24 V DC respectively.

Test points are provided at the back of the equipment to monitor the necessary test parameters. With 1mW output power of Transmitter & Receiver is designed to work with -22dB attenuation.

The equipment is designed to work satisfactorily with temperature variation of 0 deg. Centigrade to 55 deg. Centigrade.

For distinct identification, the TX & RX for 2700 Hz are provided with Blue colored name plates. While those of 1800 Hz are provided with Red colored name plates.

Technical Specifications

Transmitter:

-

Supply Voltage: 24VDC ± 20%

-

Carrier Frequency: 1800/2700 Hz ± 2%

-

Modulation Frequency: 65/85 Hz ± 1.5Hz

-

Power Consumption: 1.2 W max at 24 V DC

-

Output Level : 1mw/3mw/5mw + 10% , - 5%

-

Line Impedance : 600/1120 ohms

-

Nature of Modulation: Narrow band FM

Receiver:

-

Supply Voltage: 24VDC ± 20%

-

Carrier Frequency: 1800/2700 Hz ± 2%

-

Modulation Frequency: 65/85 Hz ± 1.5Hz

-

Power Consumption: 8 W max. at 24 V DC

-

Input Sensitivity: -19dBm

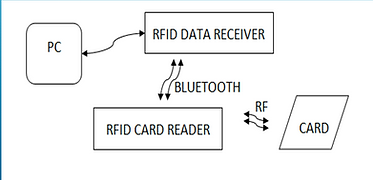

RFID

![RFID Wall Mounted[1].jpg](https://static.wixstatic.com/media/a3d9a3_eb9de58f3eae4368b17538ef8d13afc7~mv2.jpg/v1/fill/w_372,h_261,al_c,q_80,usm_0.66_1.00_0.01,enc_avif,quality_auto/RFID%20Wall%20Mounted%5B1%5D.jpg)

A.K.G. Electronics Industries was established in 1978 initially as an R&D unit, supporting the needs of the Indian Railways. Immediately on its inception it was also recognized by The Government of India (Dept. of Science & Technology) as an approved R&D unit. The company is a certified supplier of the Indian Railways and has the SSI, NSIC, and ORION Register Inc., U.S.A., Certification for ISO 9001:2000. Through its in-house efforts, A.K.G. Electronics Industries developed the intrinsically safe mines communication systems as its first product and brought out the prototype in 1979, which with its various models are used extensively by several mines in India. In 1980, Railway signal equipments like Token Less Block Instruments and Track Magnets, which are the most important part of total automatic warning system were taken up for development and subsequently by combining the innovative technology with an intimate knowledge of the customer’s application and mission the product helped replace imports from Germany and Japan. Since then the Railways use AKGEI’s warning systems. Today, AKGEI continues to diversify its offerings through partnerships into areas like wiring and cabling products for electrical structures.

about AKGEI